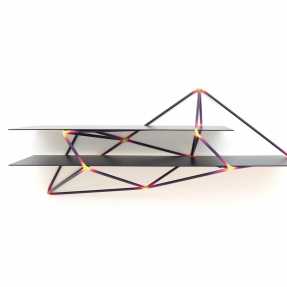

Design duo Clemens Weisshaar and Reed Kram used custom software to adapt and strengthen the branch-like metal joints of this collection of 3D printed furniture.

The Multithread collection was devised using a software application created by Weisshaar and Kram, which can analyse the forces acting on supports for a slab – in this case a table top or shelf – and automatically alter the shape of the joints to enhance their load-bearing strength.

The video explains that while standard joints work well for symmetrical loads, an asymmetric load places irregular stresses on the joint.

The Multithread process adapts the joint for asymmetric foces, adding support where required by twisting the joint or increasing its mass. Once finalised, the design is exported as a set of digital blueprints to be 3D printed in a selective laser sintering process, which applies powdered metal in layers to build up a shape.

Tubes are CNC-cut to length to connect the finished joints before the base is painted to illustrate the forces at work, with yellow denoting areas under most stress.

designer: clemens weisshaar & reed kram

producer: nilufar gallery

period: 2012

Multithread by Kram/Weisshaar from Dezeen on Vimeo.